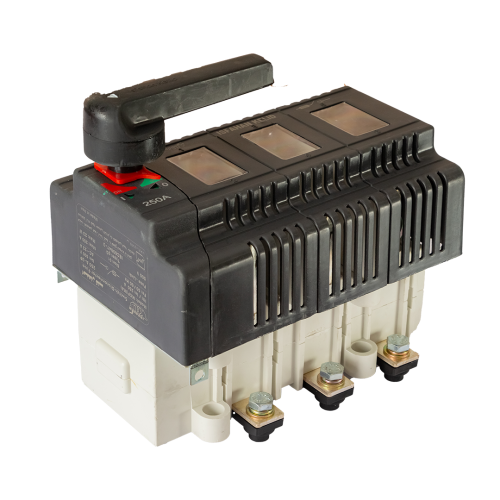

Alpha Fused Rotary Switches (IKA)

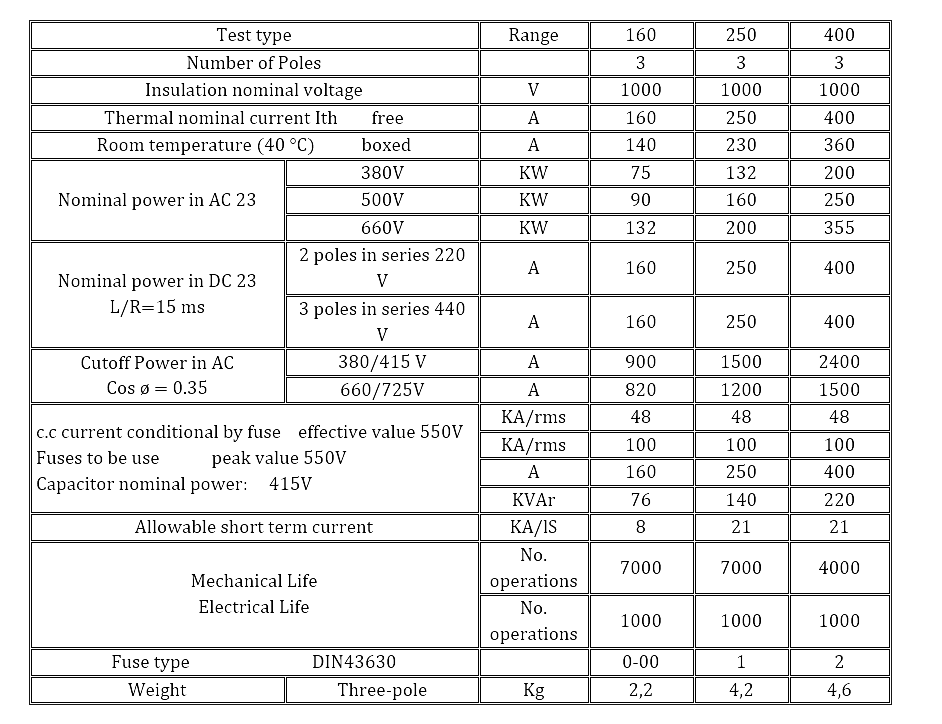

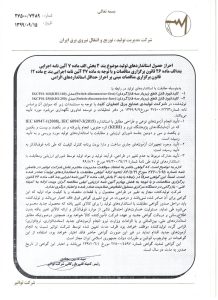

Alpha (α) fused switch can be disconnected under load and is produced in nominal currents of 160, 250, and 400 amps in accordance with international standards IEC 60947 and VDE 0660.

This switch is used to disconnect and connect ohmic, inductive, and capacitive loads such as transformers, AC electric motors, and capacitors.

Special benefits

Easy installation

Due to the presence of protective covers, the excess materials on the body of the switch are removed. In this case, installing the switch will be much better and easier.

LED indicator

The switch of the Alpha model (α) is similar to the Landa model switch (ʎ) in the protective covers, the protective cover lock, and the existence of insulation between each phase. The only difference between these two models is the presence of LED indicators in the Landa model.

Increase mechanical strength

In order to increase the mechanical strength of the movable arm, SMC raw materials have been replaced by BMC materials in the structure of the movable arm body as polymeric materials with very high mechanical strength.

Increased contact surface

The input and output platinum pieces in phase T (third phase) have been relocated due to the problems of installing the ingot on its body and the lack of space for installation, and thus, the contact surface is increased while facilitating installation.

Reduce power losses

Power losses in this switch are reduced due to the increase in the contact surface between fixed and moving platinum.

More protection

The Alpha model switch is a suitable replacement for IKCF 01 fused rotary switches. This switch has a better degree of protection than previous models due to the protective cover of the fuses.

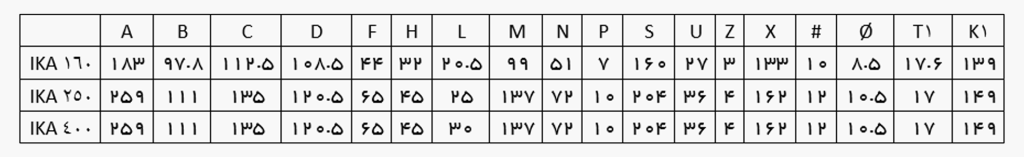

General information

Request a free consultation

Our experts are ready to answer and advise you.